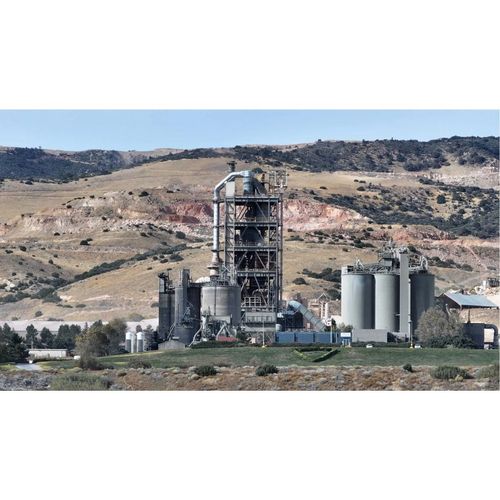

National Cement of California Finalizes Agreement with DOE for Development of Lebec Net-Zero Project

December 25, 2024

BY National Cement of California

Advertisement

Advertisement

Related Stories

Deep Sky Secures First-of-its-Kind Financing with Finalta Capital to Advance Carbon Removal in Canada

Deep Sky has secured an $11 million bespoke credit facility from Finalta Capital to finance its flagship Alpha carbon removal facility in Alberta. Alpha, the world’s first cross-technology carbon removal site, became North America’s first DAC project to sequester CO₂ underground.

Boral has successfully trialed concrete made with recycled aggregates recarbonated via carbon capture technology from its Berrima cement plant. The pilot, supported by the federal CCUS Development Fund, replaced 50% of natural coarse aggregates with recarbonated recycled materials in a low-carbon mix.

MODEC is Awarded Approval-in-Principle from American Bureau of Shipping for LCO2 Floating Storage and Injection Unit

MODEC has received Approval in Principle from the American Bureau of Shipping for its Floating Storage and Injection Unit (FSIU), designed to handle liquid CO₂ at sea. The unit can receive, store, and inject up to 10 million tonnes of CO₂ annually into subsea reservoirs, eliminating the need for onshore storage and pipelines.

Capsol Technologies has been awarded a feasibility study for a European Bioenergy with Carbon Capture and Storage (BECCS) project. The biomass-fired combined heat-and-power plant under evaluation could remove more than 200,000 tonnes of CO₂ annually while supplying renewable heat to local communities.

PTTEP Moves Forward with Thailand’s First CCS Project at Arthit Field to Advance the National Net Zero Goal

PTTEP has reached a final investment decision on Thailand’s first carbon capture and storage project at the Arthit gas field. With operations expected to start in 2028, the project will capture and store up to 1 million tonnes of CO₂ annually while aligning with the nation’s Net Zero targets.